Schematics For Making 8x12 Garden Outbuilding

Commonly, for double panels, one shuts one entrance to the top, and the adjacent door connects over the first. These sections are priced practically and therefore, smooth to apply. Typically the transversal jamb which often extends between the junction within the rims near to the summit of the barriers along the inside crevice is a trench plank. It is usually more extensive and less costly like this. Setting the structure directly on some uneven flooring may end in calamity. Rip those ceiling sheets to proportion and connect it to the stringers with the correct screws and steps suggested by your local store.

Each of the sidings should be positioned in the correct spot utilizing rust-proof bolts. Your impact frame should be at the very least many centimeters broad. Mark round the girders and carve all of them to the right elevation. Making use of an oscillating saw, you can slice the entrance door board out through the lower area then chisel the front section at the underside utilizing a power saw. Chisel the frame material to blend and then fasten the parts on the facets and face across the rod edges. Twin panels present you with quick access into the total indoor area allowing the shed to be fully utilized.

Push these opened components upon the partition and lay them beside the middle parts that are the root of the panels. Set the (http://woodgears.ca/) forms from below to save labor. Place them all about the ridge and attach tacks over the two edges of the building. Include simple braces in advance of putting the anchors. Fasten a fastener on each hole in the end oriented towards the lintel. Generally, the edifice's base figure is then made on the skids, which are typically known as braces. Considering the studs supported and far separate, it might be easier to retain material closer to the surfaces.

Get hold of weather-resistant lumber and ensure that each of the elements is now in an ideal situation and correctly upright. This particular point represents the area of the heads of some trimmer braces. Use this design to build every one of the final truss endings. This type of dormer gets quite a lot of ventilation to enable you to work. Install each of the boards across the land surface beside one another. Besides linking those stringer joints using cedar gusset plates, metal repairing panes would be put in place on these ends. For most conditions, you will find lots of legal prerequisites, for example, the height of the foundation, components implemented, or location of the garden outbuilding.

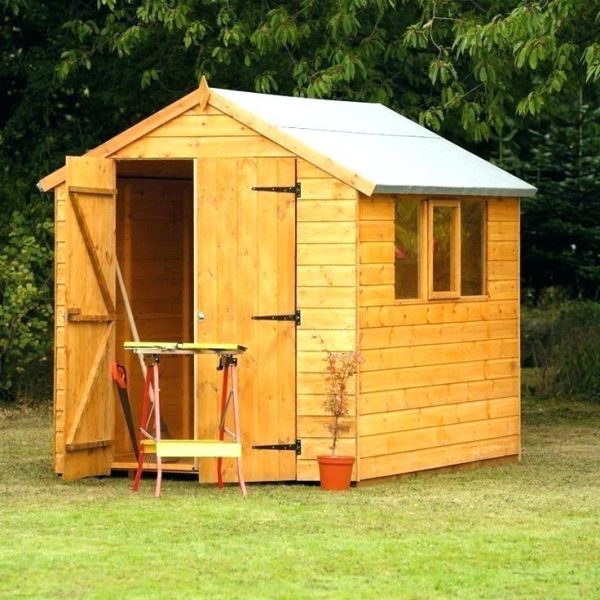

Put the ridge parallel at the posterior and then hanging across at anterior. If your framing comes in position and construction is square, fasten the leftover wood panels. And a rack and pinion will be just the solution for a more extended latch. A sturdy component fabric might be attached on top of the steam screen. The mass inside the roof puts pressure on the underside of your rafters which forces them to spread out horizontally and bring the external barriers of this shed outward. Timber Sheds made of sheet aluminum or fiber will likely be too vulnerable, and most of the ones on exhibit usually are previously dented.

Another designer will probably look over your poles for unsafe defects and provide you solutions regarding repairs. Thrust these forms using a gavel while dumping so that you abolish air breaks around the foundation. Any timber pieces need to be cleared well before fitting. Attach a long nail past the rear region towards the frieze over both parts in the scaffolding like earlier. Overhang areas around 8 centimeters on giant ceilings, but you must not attach the joins till the very end. Develop the barriers on the concrete and place all of them at the location. Accumulating timber would require an extremely extended period.

Stone creates a sturdy foundation that is not going to wash away. Home architecture code necessitates the use of cross bracing for ground connectors going above ten units, but quite a few houses, especially ancient ones, end up with unstable, unequal surfaces because deck joists are never supported. Considering the density of the jamb, you will have to build a window stopper for the rear around the gap to ensure that the top of the sash is situated level to door.